I often get asked which order to trim, size, clean, or anneal my brass. I have created this brief timeline outlining the reloading process and the order in which I do it. Also, I'd like to outline how and when I will perform the basic procedures, along with a few minor tweaks and tips.

To reiterate, this is the way i do it. There is nothing to say which way is right or wrong , or that my techniques are correct. After 40 years of reloading, this method has consistently proven itself to me and how i shoot.

Some important safety steps first.

- When reloading your cases, ALWAYS WEAR EYE PROTECTION and point the priming tool away from your face to prevent injury.

- Keep detailed notes of the rounds you reload and correctly label ammo boxes. The worst-case scenario is a box of ammo in the back of the gun cabinet that you do not know the contents of.

- Do not mix powders, even if they are the same type. Please do not do it.

- Personally I prefer to have two reloading trays in my set up, one to the left of the press and one to the right. As I am right-handed, I move processed cases from left to right. Once I have completed the operation, the case will be transferred to the right-hand loading tray, which will help to prevent double charges, unsized cases, and other issues occuring ("contamination of operation," as I like to call it).

- Try to eliminate distractions; you need to concentrate on your actions. If your mind is not in the right place for reloading, come back to it when it is.

DO NOT RELOAD IF YOU ARE INTOXICATED!

GUNS, ALCOHOL, & DRUG MISUSE DO NOT MIX WELL

TAKE YOUR TIME WHEN RELOADING; IT'S NOT A RACE!

Staying Legal.

The following is a concise and straightforward guide to staying legally compliant in the UK while reloading. It should be apparent to us all; I'm posting it on the site to help the occasional person who is new to reloading and for people who may need clarification.

Please do not reload calibres that are not on your certificate. Fellow shooters may ask you to reload for them once they see how well your reloads perform but having ammunition in your possession that you are not legally allowed to hold is an offence. If they are insistent or want to share equipment, that is fine permitted they are present whenever you load for them.

Only reload the quantity you are allowed to hold on your certificate. Most forces will consider a primed case to count in your allocation. As we all know, different forces interpret rules differently, so it's a good idea to always check with your force for clarification.

I often get asked how much powder we can store. This differs from force to force. Recent research suggests that approximately 15 kgs appears to be the average figure. If in doubt, ask your local Firearms department.

Abbreviated Timelines

New Cases (Basic) Step 1 > 4 > 5 > 6 > 10 onwards

New Cases (Advanced with neck turning) Step 1 > 16

Once Fired Brass (Not needing any extra work at this time) Step 1 > 2 > 5 > 10 onwards

Once Fired Brass (Needing a complete trim, clean cycle) Step 1 > 16 missing out Step 7

Step 1 - Visual Case Inspection

The first step in reloading your round is visually inspecting your cases, whether they are once fired or new. Look for splits, case head separation, dents, or any other issues that do not appear safe or correct.

If you are still unsure about what you are looking for, a quick guide to describe case faults can be found here. If you are still further unsure, please ask someone who knows what to look for.

- If you are starting with brand-new, virgin brass, you can still visually check it and then move on to step 4

IF YOU FIND ANY AND YOU ARE IN ANY DOUBT BIN THEM!

Step 2 - Universal Decapping

If you think your brass will require any extra procedures, such as trimming or cleaning, it's a good idea to remove the primer without resizing your brass and do that later in the timeline. We can pop the primer out without resizing the case using a universal decapping die. Please ensure you have the correct one for your calibres, since there can be large and small flash hole variants which differ in size 0.060" for small and 0.080" for large.

Step 3 - Case Length Trimming

As we repeatedly fire our cases, they can lengthen after firing. We can counteract this by trimming the case length to a predetermined length using case trimmers. If my brass is too long and needs to be cut, this is when I will do it. I will usually use a known trim length for that calibre, which can be found in manuals or on-line. Or if one is not available, I will pull 20 random cases from the pile. I will then measure the complete length of them all to find the shortest case. Once I determin the shortest case, I will trim the whole batch to that length. This will ensure that all cases in that batch have a uniform case length. I use a lathe-style trimmer, as it suits my needs well.

Step 4 - Chamfering & Deburring

Once I have trimmed my brass, I need to chamfer the inside and deburr the outside. I usually do this by hand if it is a target gun, as I get a better feeling for the right amount. I will happily use an electric machine if it is a more do-all use rifle. I usually use a VLD-style inside neck chamfer tool and an everyday RCBS deburring tool on the outside. I do as little as I can get away with in both operations. Please ensure you do not leave a knife-edge rim in your case, as this will not help with consistent neck tension, especially when using bushing style dies. A quick twist with the hand is all that is needed.

Step 5 - Primer Pocket Cleaning & Uniforming

Switching to the other end of the case now, I will always clean the primer pocket whenever the case is to be reloaded. I use a primer pocket uniforming tool to do this. I don't like wire brushes, as they can scratch the inside of the primer pocket. As I am using a uniformer all the time. I do not need to do any extra pocket work as it will uniform and clean the pockets simultaneously. If I am using new brass, I will run the unifomer in the pocket to help square up the primer pocket floor and aid in seating the primer to the correct place up against the flash hole.

Primer pockets are usually made by punching the case head with a stamping tool. They tend to leave a rounded corner at the bottom of the pocket. The problem is that when we seat a primer, it will not reach the pocket floor but will be slightly short of it, as it hits the rounded corners. By uniforming the pocket, we will square up the bottom corners, allowing the primer to sit flush against the floor near the flash hole, where the best ignition results can be achieved.

When cleaning and handling your brass, please always look for any defects or areas that require correction.

Step 6 - Flash Hole Deburring

While uniforming the primer pocket, I will also deburr the flash hole uniforming tool. This is a one-time job best done when your brass is brand new. You don't need to do more than that; by doing this, we will allow the flash from the primer to be much more uniform in size and help with more even powder burns. Small burrs are left inside the case as a result of machining, which creates the flash hole, and these tools will clean it out.

Step 7 - Neck Turning

Neck turning is an advanced reloading procedure for reducing the brass thickness of the case's neck wall. There are two types of neck turning: turning the case neck and lightly hitting it. 80% of the surface is smoothed out to even out the thick and thin parts of the wall thickness. We do this especially when using bushing-style dies to help achieve even neck tension (grip) of the neck onto the loaded head.

The second reason is that if we shoot a custom gun with a tighter-than-usual neck. We must trim the neck wall thickness to a particular dimension to allow the case to enter the tighter neck in the custom chamber. For additional "how-to" neck turn information, visit YouTube where this can be covered in greater depth.

Step 8 - Case Cleaning

Case cleaning is not necessary! However, shooting at extended distances will help with more consistent results, and it is always rewarding to produce nice-looking rounds. Plus, if you are stalking, for instance, and drop your cases in the mire, you do not want to take all that debris into your reloading dies.

I do not clean every single time, but I usually clean every third to fourth firing when I plan to trim or when they appear to need annealing.

I use the stainless pin wet method, cleaning them for 2 hours. Then dry them outside on a nice, warm day or in the airing cupboard, not in a cooker.

There are various levels of cleaning, starting with vibratory cleaners, which are great for the outside. They leave a nice and shiny case, but require assistance with the internal carbon build-up and are noisy. We then proceed to ultrasonic cleaners, which require a longer cycle to ensure thorough cleaning. Typically, we need to cycle them 5-6 times to achieve decent results. Still, they will clean inside and outside; once again, they must dry, as suggested above.

The third option is wet tumbling with steel pins, which I occasionally use when cleaning my cases. It will clean as thoroughly in two hours, inside and out. Job done. They will be clean on the inside but dull on the outside. If we desire shiny cases, run them through a vibratory cleaner for 30 minutes to polish them up. A bit belt 'n' braces! Shiny is nice.

Once the inside carbon is cleaned out, long-range shooting becomes more accurate, and we can more consistently measure the volumetric burn of powder from shot to shot.

Step 9 - Annealing

I usually run my brass through my annealer every time I reload my cases. I use an AMP electronic induction annealing machine. They are certainly more consistent and repeatable than the gas versions. They are also a lot easier to set up and a lot safer to use. I have transitioned from a gas flame-type annealer to the AMP, and the difference in annealing quality is night and day. If you have a gas annealer, I will anneal as little as possible. The electronic induction method used in the AMP system is repeatable and consistent, allowing it to be used every time you reload your cases, if desired.

*Step 9a Rollsizing Brass (Clickers)

If you are shooting cases that, once fired, persist in giving you hard-to-lift bolts. Which are also known as "clickers". There is a technique called Rollsizing, which can resize the case to the .200 line. This is for advanced shooters only. I'm mentioning it here only to align with my reloading timeline. I won't go into specifics as further research is needed by the shooter, towards the cause and effect with "Clickers" This procedure can be done before or after annealing.

Step 10 - Sizing

*Neck Only Sizing!!!!!

I do hate neck-only sizing brass. In my opinion, it is not the best practice for live quarry shooting; how do I justify that? The problem with neck-only sizing is that after 3-6 firings, your loaded rounds can become tight on the bolt-to-chamber. Say you accidentally misplace a shot on an animal, and it needs a quick second shot to finish it, and your neck-sized brass does not chamber smoothly, or you must fiddle with it. That is not desirable in my eyes; that beast (deer, fox, rabbit), whatever it is, deserves a clean, humane death, NOT to be delayed and suffer.

For target shooting, neck sizing does not offer enough consistency for my liking, and the tight bolt issue can be problematic, especially when shoting prone and trying to shoot smoothly. Messing about with tight bolts, etc., does not help with that.

Some will argue that neck sizing will help prolong the brass's life, which is partially true. Consecutive sizing can harden the brass, making it more brittle and susceptible to splitting and cracking.

As for forming the brass in the chamber and neck sizing only to keep the chamber-formed case, you will be back to the scenario of 4-6 shots before tight bolts, etc., so why not full-length size appropriately from the get-go? This will also help maintain a more uniform case volumetric measurement.

With new modern brass and annealing techniques, there needs to be a better argument for neck-only sizing.

Now that we have covered the neck sizing argument and dismissed it, we will return to my method.

**Full-Length Sizing

I use this method exclusively for all my reloading across 20 or so calibres.

Once the brass is fired, using the full-length die will correctly size the neck and reset the shoulders (headspace) to the correct dimensions; it will also pop out the old spent primer simultaneously unless I've already deprimed as in Step 2.

How I set up my sizing die in the press,

I make sure that the correct shell holder is in the press. I drop the press handle and raise the press ram towards the point where it will eventually meet the bottom of the sizing die. I will then start to screw the sizing die down into the press, making sure that I back the outer die lock ring is backed off as well. I will continue to adjust the sizing die until it just barely touches the top of the shell holder. Then, after lifting the press handle and dropping the ram out of the way. I will further tighten the die by no more than 1/8 turn. Then screw down the outer die lock so that it is only finger-tight against the top of the press, to help keep the die in position during the sizing process. You will know if it is correct when you size a case. You will get a slight "cam-over" effect on the press handle. It's hard to describe, but you'll see what I mean when you experience it.

Please take a piece of brass that requires sizing and lubricate using your preferred method, ensuring that only a minimal amount of lubricant remains on the case. Ideally, you want to lube the neck into the shoulder and the top third of the case. A handy tip for lubrication is to use a cotton bud tip and apply a small amount of lubricant to the inside of the case's neck, which helps lubricate the expander ball inside the die. The expander ball is part of the die that helps size the neck, so keeping it lightly lubricated helps prevent it from becoming dry and dragging.

If you purchase new brass, running it through your full-sizing die is an excellent idea to help eliminate any minor neck dents or dings that may have been incurred during shipping and handling.

We aim to move the shoulder back by .002", also known as resetting the headspace.

If you did not perform step 2 this time, the sizing die must also eject from the primer. Once you size the case, the decapping pin must protrude from the bottom of the die, just enough to eject the primer cleanly.

***Advanced Sizing

If you use full-length bushing dies, they can be set up in the same way; you need to determine the correct bushing size for the die. The bushing die section in the shop provides further clarification on this.

Regarding step 1, please use the full-length size only. Please ensure that your sizing die makes contact with the shell holder when setting it up, as described.

Step 11 - Neck Tension Control

A new practice that has become extremely popular, and which I now include, is setting neck tension after sizing. I do this every time after sizing, using a custom-ground neck tension expander. After testing, I have found that the best expander to use is either 1 1/2 thou (0.0015") or two thou (0.002") under the calibre size. For example, a .223/4 Calibre would use a .221/2" expander, etc. When using the expander, I dip the case neck in a graphite lubricant, such as Redding Imperial Dry Neck Lube, to help ease tension setting. Any graphite left in the neck is acceptable to remain there, as it will help smoothly seat the projectile when we reach that point. You can use these with bushing-style or standard non-bushing-style dies. A slightly tighter bushing than usual yields better results when using this type of bushing.

Just before we start construction of our rounds, I'm going to add a little extra advanced section here.

Component sorting

Do we need to sort our components, and what are the benefits of doing so?

This is a question I am frequently asked, so I have written this brief article to address it in two ways. The first is for a general shooting style (stalking, predator control), and the second is aimed more towards the long-range precision shooting styles.

For the general shooter, sorting components by the methods shown below will have little to no impact on their results. Their results are more than acceptable as long as they are diligent in their reloading and work method. On average, they are looking for a 1 MOA gun or better, meaning a one-inch group at 100 yards or better.

Moving on to the more dedicated long-range shooters. Sorting components becomes more desirable for more consistent ammunition; however, the gains are relatively small compared to the benefits of decent load development. The further the range is extended, the more these small benefits are magnified.

Primers - The most common method for sorting primers is to segregate them based on their weight. The gains are minimal and will be ignored by most shooters. Most will settle for that if the primer sits correctly in the pocket when seated; that's good enough.

Cases - Target and long-range shooters are looking for flat-shooting guns, which can be achieved by achieving more consistent projectile velocities. We need to maintain a constant cartridge pressure when firing our rifles.

Sorted cases will be more advantageous than non-sorted cases, resulting in greater accuracy. Different methods can be used to sort the cases; the first is by weight, sorting into groups of similar-weight cases, and the second is by case volume using the "H2O" method. In this method, we will plug the primer pocket to prevent leakage. We will then weigh the empty, plugged case on an accurate scale. We will then fill the case with distilled H2O (water) until it is filled, and we have a slight curve on top of the case where the water is under tension just before it spills over; then we re-weigh the case and subtract one from the other, this will give us the total case volume. We can then group cases by similar volume. The cases in these sorted groups will provide more consistent pressure as their volumes are identical. When we have more consistent pressure in our cases from shot to shot, the gains are evident in fewer vertical differences between our shots on the target, resulting in flatter shooting guns.

Projectiles - Sorting projectiles is crucial and can be accomplished using several different methods. When sorting projectiles, I will sort as many of an identical "lot" number as possible, ideally 4000 or more, which I find gives me a decent amount in any sorted group to load a substantial amount of ammunition without having to revert to another sorted group of differing measurements. I occasionally sort by weight; I prefer to some kind in 0.2 grain intervals of the selected projectile. Nowadays, I measure the overall length (OAL) of the projectile, which is the distance from its base to the meplat. I usually sort them after trimming the meplats and pointing them. The gains are apparent as we will see the projectile's more consistent flight path.

Propellants - I don't sort my propellants, but I will only use powder from the exact lot numbers that iI used to do my load develpoment with. If I have to use a different number, I will redo my load development.

Now we can construct.....

Step 12 - Priming

Priming is my first step in reconstructing the round after all the case prep is done! I only want to handle the case as much as necessary once it is resized, as I want to maintain the neck tension I have introduced using the sizing die and neck tension mandrel after that. I will always use a hand priming tool, as the feel of a hand priming tool is better than that of a press-mounted one. It is a lot easier to feel if something is going wrong or is incorrect. After seating the primer, I will check for it to be seated correctly in the primer pocket up against the flash hole and slightly just below flush of the case head.

Step 13 - Powder

Adding the powder now to the primed case, I will always weigh every powder charge; I DON'T dump them straight out of a powder thrower into a case; this can be dangerous. If I use an Electronic powder weigher/thrower, I will set it to .1 grains under the desired weight I am after and trickle the last tenth up manually. Adding a tenth of a grain is easier than removing it if you get an over throw. All electronic throwers are accurate to within ±0.1 grain, so I add the extra; it is easier and faster.

If I use beam scales, which I do use for some of the more precision calibres, I will set up my phone camera in front of the scale and view the level indicator through the camera. It is ultra-accurate and easier on older eyes.

Remember that there are 7000 grains to a pound, and we are talking about tenths of a grain, where one kernel can weigh, on average, .03 of a grain. Therefore, attention to detail is crucial for consistent accurate and safe rounds.

Step 14 - Projectile Seating

The final step in the construction process for your ammo is now the most critical for consistency.

When setting up a seating die on the press, I like the back of the seating stem (the part in the middle) off in the die and then screw the outer die body down until touches the shell holder. Then, as I try to seat the projectile in the case, I can screw the seating stem slowly down (in the middle) to reach my desired seating depth—screwing the stem down bit by bit and measuring the length with callipers. Once I have achieved the correct seating depth, I will lock off the die with the die lock, but only hand-tight.

This is a quick tip to dispel some myths about (COAL) Complete Over All Length measuring for seating depth. This method is a good starting point, but I need to be more consistant. I want to use an OAL gauge, which is incorrectly named, but I'll I'll go with it for now. Using an OAL gauge, we can measure the distance from the base of the case to the Ogive on the projectile, providing an accurate seating depth figure for comparison and use. The Ogive is a datum point usually found where the projectiles bearing surface meets the point where it curve's towards the case tip (called a meplat). Using a modified case, we can control the correct seating depth for any projectile; some projectiles prefer jumping, while others prefer being close to the barrel's lands. Only load develpoment can determine this and is further covered in the following section.

Another factor of measuring base to Ogive is that we get repeatable seating depths. The problem with COAL measurement, especially when using polymer-tipped heads, is that they can vary by 50-60 thousandths of an inch; yes, the polymer tips can change that much.

As for crimping, I do not; when I say that I do not add any extra crimp to my rounds, all seating dies are designed to add a very small taper crimp. We can further measure this crimp by controlling neck tension in step 11. If you are shooting a high-recoiling magazine-fed pistol-calibre gun, you may need to add an extra crimp.

Alternatively, to seat on a standard single stage press, we can seat our projectiles using an arbor press and Wilson inline seating dies. I will use this method for extreme accuracy in the finishing stage. An inline seating die will fully support the case when the projectile is being seated. Supporting a case like this keeps the case-to-head alignment concentricity to the tightest tolerances.

I will also use an AMP Press to see the seating force needed when seating my rounds for more advanced control of loaded rounds and futher segregation of "Fliers".

A top tip is to partially seat the projectile in the case and. turning the case round in the shell holder by 180 degrees, then fully seat the head. This will half the concentricity in the case of projectile alignment and add an accuracy gain

Also in this section, I will mention meplat trimming and pointing, as I have experimented with both methods and achieved good results. If I use projectiles with large open meplats that look inconsistent, I will trim and point them or if they are smaller and more uniform iI will only point them using the Whidden system. If they look okay, I tend to leave them alone. If I cut and point, I will always trim first, taking off as little as possible, then point the meplat as little as possible.

Step 15 - Last Check

Before shooting, the final step is to physically inspect them one last time. You are looking for anything that does not look or feel right. If you find any issue's or have doubts, use a bullet puller to remove them. You can always reload them...

Do Not Forget To Use Labels On Your Ammo Boxes

Step 16 - Shooting Them

Shoot them and revert to step 1

As you can see from the 16 steps above, this is how I reload, not always needing to do every step every single time. I will always stick to the same order of case preparation leaving sizing to do, just before priming.

Sizing the case and setting the neck tension are the last steps in case preparation before I prime the brass. I want to maintain the neck tension once it's set.

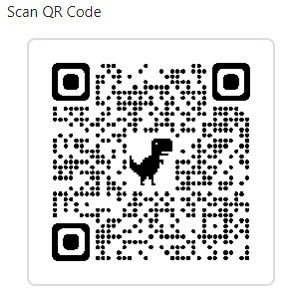

Click HERE for a link to a YouTube video I made a few years ago. It's a bit dated now, as it's not 4K, but the information remains current and is still relevant to modern shooting techniques.

PLEASE NOTE - IF, FOR EXAMPLE, YOU ARE RELOADING ON A SUNDAY AFTERNOON AND GET STUCK OR NEED HELP, WE ARE ONLY A PHONE CALL AWAY. OUR PHONES ARE ALWAYS MONITORED; IF THEY DON'T GET PICKED UP, IT MEANS SPUD IS DOWN! HE WILL ALWAYS RETURN A CALL THE SAME DAY, AS FAST AS POSSIBLE,

Lastly, please remember you are not alone! We are here to help you whenever you need it. If you are half way through, we are open 365 dyas a year so just pop us a call.

IF YOU WOULD LIKE TO RE-PRINT THIS FOR CLUB USE OR TRAINING, PLEASE HELP YOURSELF

Above all, be safe and enjoy.