PROJECTILE DESIGN

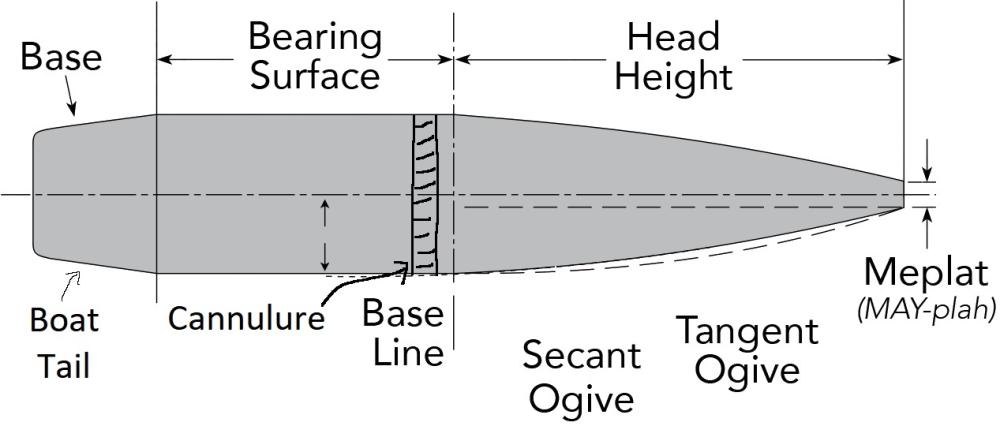

MEPLAT - Defined as "the diameter of the end of the tip of the projectile." Careful attention is paid to the meplat because its diameter and uniformity contribute to the bullet's aerodynamic efficiency.

CANNELURE - The cannelure provides a consistent crimp location. Cannelures are also found in selected bullet lines where semi-automatic or lever gun use is desired. Only found on some bullets.

BOAT TAIL - Whereas a standard rifle bullet has straight sides that end in a flat base, a boat tail bullet has sides that taper inward toward the base. The “boat tail” name describes it well because it looks like the stern of a sailboat. That shape benefits a bullet in the same way that it does a boat: by reducing drag.

BEARING SURFACE - The portion of the bullet that contacts the rifling in the barrel and directly correlates to the amount of pressure generated within your barrel, and it can have a definite effect on accuracy.

SECANT & TANGENT OGIVE - A Tangent Ogive (like our standard BTs) is less sensitive to seating depth but has more drag and a lower BC than a Secant Ogive of the same length. A Secant Ogive (like our standard VLDS) has a higher BC and lower drag than a traditional Tangent Ogive but can be pretty sensitive to seating depth.

HYBRID OGIVE - A Hybrid Ogive blends the best aspects of the tangent and secant nose shapes into one Ogive. It starts at the bearing surface with a tangent section that will align itself more effectively when the bullet contacts the rifling. Beyond this section, the shape transitions into a secant section, proven more effective in the wind. The result is a high BC bullet that is easier to tune.

CASE DESIGN

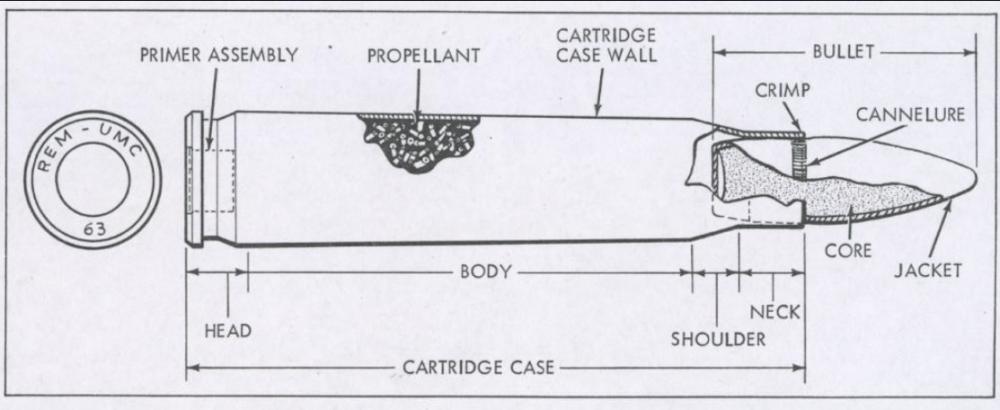

The Functions of a Modern Cartridge Case

The cartridge case provides four main functions.

It contains the bullet, primer, and powder in a package protected from the elements and feeds/ejects smoothly in the firearm.

Aligns the bullet in the chamber

Expands to seal the chamber during firing.

It acts as a heat sink, absorbing the heat from the combustion and removing it from the chamber when the cartridge is ejected.

Mouth - The open part of the case where the projectile sits.

Neck - The part of the case that contacts the projectile along its bearing surface. The case neck is responsible for holding the bullet. The thickness of the brass is typically 0.010 to 0.015, and ideally, the neck diameter is .001 to .0015 below that of the bullet diameter. This creates an interference fit with the bullet responsible for creating neck tension. Neck Tension plays a critical role in holding the bullet in place while it sits in the magazine, is being chambered, or even when extracting a loaded cartridge from the case. The amount of neck tension required varies drastically depending on bullet weight, calibre, recoil and firearms.

Body - The body of the case, sometimes called the Powder Chamber, performs two primary functions. The first is to contain the powder charge, and the second is to swell under pressure to form a gas-tight seal between the chamber and the case. This seal prevents hot gasses under pressure from being ejected into the action, potentially injuring the shooter. This seal also holds the cartridge in place. The gripping power is such that it substantially reduces the amount of force that is transmitted to the bolt face.

Shoulder - The transition of the case body into the neck on a bottle-style case; on straight-walled cases, there will be no shoulder. In most cases, the shoulder is responsible for head spacing the cartridge in the chamber. This headspace determines how deep the cartridge sits in the chamber in reference to the bolt face. The brass on the shoulder also tends to be thin and soft, which can cause issues.

Head—The case head is the thickest and hardest part of the case, and, consequently, it is also the strongest part of the case. The case head contains the flash hole, the primer pocket, the headstamp, and the extractor groove. Some cases also headspace off the head of the case via a rim or a belt.

Primer Pocket—The primer pocket provides two essential functions: it retains the primer by handling and firing the cartridge and sealing the gas within it. The second function is to seat the anvil in a Boxer Primer so that the firing pin can crush the primer pellet between the anvil and the primer cup.

Webb - The case web connects the case body and the case head. This crucial junction can weaken after repeated firings as the brass is stretched under firing and then compressed when sized in a sizing die.

Extractor Groove - The extractor groove provides a surface for an extractor to hook onto and remove the case from the chamber. In the case of rimmed cases, there may be a slight undercut on the rim to aid in the extractor gaining a more positive purchase on the case. Each cartridge's extractor groove is typically shaped differently depending on the intended firearm. However, all exist to perform the same function. Could you provide a means to remove the cartridge from the chamber? Due to the forces involved in some semi-automatic rifles, the groove is subject to substantial pressure.

Flash Hole—The flash hole is typically .060 in diameter and ensures that the primer's sparks ignite the powder charge. It also allows gases to flow back into the primer during combustion. The size and uniformity of the flash hole do impact pressure and velocity. That said, most of the flash holes I’ve seen have been uniform in diameter, all falling between 0.060 and 0.080in.

As you can see from the above diagram, there are several terms when referring to cartridge cases. The most important are the neck, shoulder, rim and head. All of these can give vital clues to identifying a cartridge case. The neck can give an approximate calibre (although the diameter inside the mouth is more accurate), and the slope of the shoulder can differentiate between similar cartridge cases.

As this second diagram shows, the bullet is the projectile that leaves the weapon at high speed when the cartridge is fired. A cartridge case should never be called a bullet! It needs to be corrected! The bullet itself has a core and a jacket, along with a groove called a cannelure. This can also help ID-specific bullets.

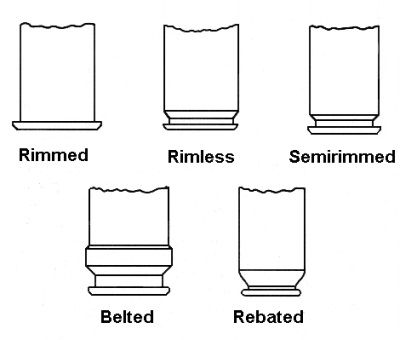

Apart from the headstamp (the marking on the base of a cartridge case), the rim is perhaps the most important. There are various types of rims.

Cartridge cases generally come in these three shapes:

Straight – where the case diameter is approximately the same along its length.

Bottle–necked – where a wide-bodied case is, just before the case mouth, reduced in diameter to that of the bullet. This allows a much larger propellant volume to be used, and consequently, higher velocities are obtained than in straight–sided cases.

It is tapered – where a broad–based cartridge case is gradually reduced in diameter along its length.

The cartridge case can be subdivided into five categories according to the configuration of its base.

Rimmed - These have a flange at the bottom, more significant than the diameter of the body of the cartridge case. This flange enables the cartridge to be extracted from the weapon in which it is used. When describing rifle ammunition and the metric method of designating the

ammunition used, these are often identified by an ‘R’ after the case length measurement.

Semi–rimmed - These have a flange slightly larger than the diameter of the cartridge case and a groove around the case body just in front of the flange. When describing rifle ammunition and the metric system used, these are identified by ‘SR in the cartridge designation.

Rimless – In these, the flange diameter is the same as the case body, and there is, for extraction purposes, a groove around the case body just in front of the flange. There is generally no letter system to designate this cartridge base type. Self–loading pistols are designed for use with semi–rimmed or rimless ammunition.

Rebated—This has an extractor flange less than the cartridge case's diameter. The designation used in the metric system is ‘RB’. This type of cartridge case configuration tends to be reserved for high–powered cannon ammunition.

Belted case – These have a pronounced raised belt encircling the base of the cartridge. This belt is for additional strength in high-pressure cartridges. The metric designation is ‘B’. This cartridge case is generally only found in high-powered rifle cartridges or military cannon ammunition.

This terminology is a little complicated. However, it isn’t! A rimmed cartridge is called that because the very bottom portion of the head, the ‘rim’, is wider than the main body of the cartridge. With a rimless cartridge case, the rim is precisely the same diameter as the cartridge case, which starts above the extraction groove. Semi-rimmed cartridge cases have an extraction groove and a rim slightly larger than the diameter of the cartridge case. Belted cartridge cases have a thicker ‘belt’ positioned just above the extraction groove, and rebated cases have a rim that is smaller in diameter than the cartridge case.

Courtesy of Forensics Digest & Ballistics Assistant